Quality Control

At OUTSTANDING, we rigorously follow ISO 9001 quality management standards. With a systematic quality control process, we consistently achieve a product excellence rate of 99.8%.

- Home

- Quality Control

Expertly Executed Testing Capabilities

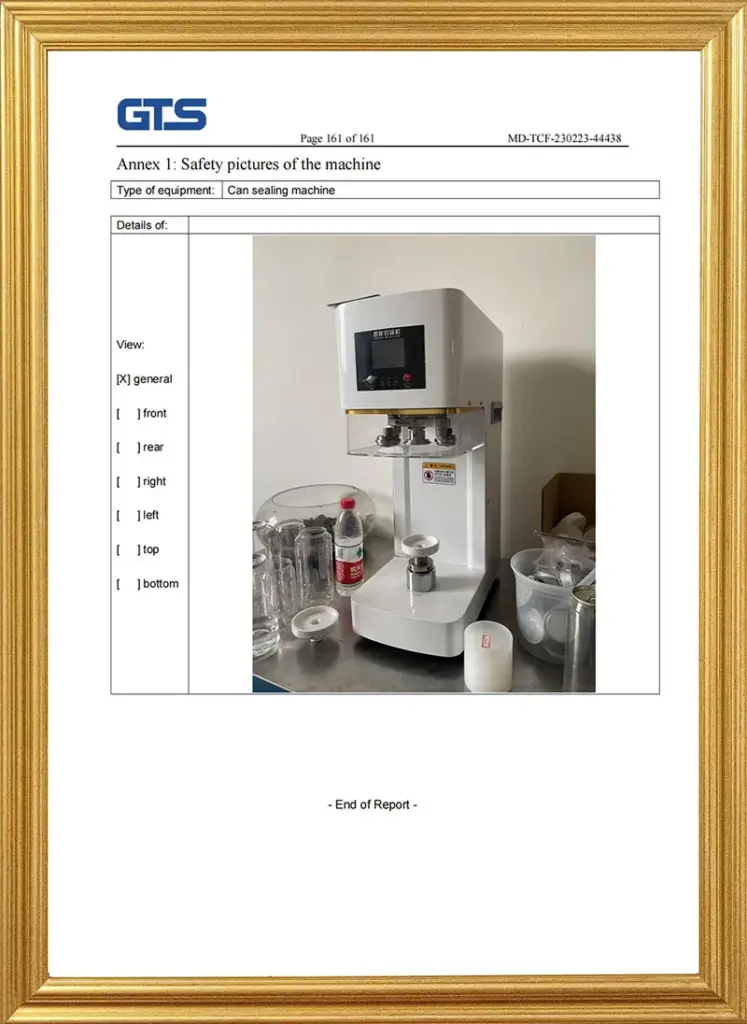

Our production team brings 10+ years of industry experience and is equipped with advanced testing equipment to thoroughly examine our plastic packaging for weight, dimensions, wall thickness, sealing, color, material properties, and strength.

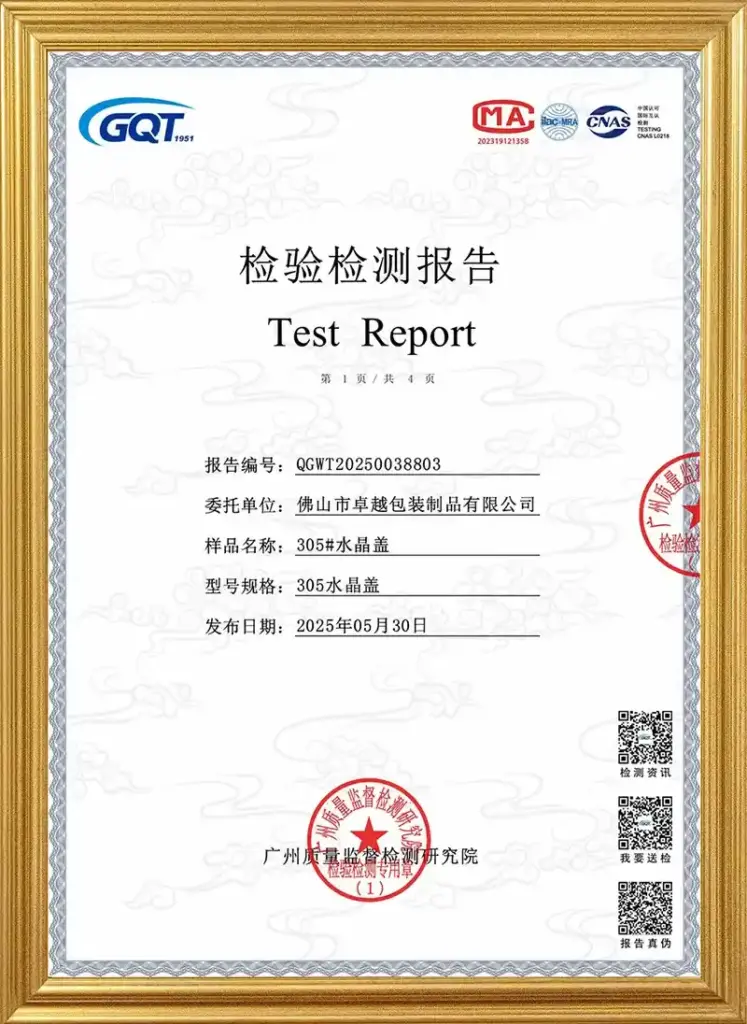

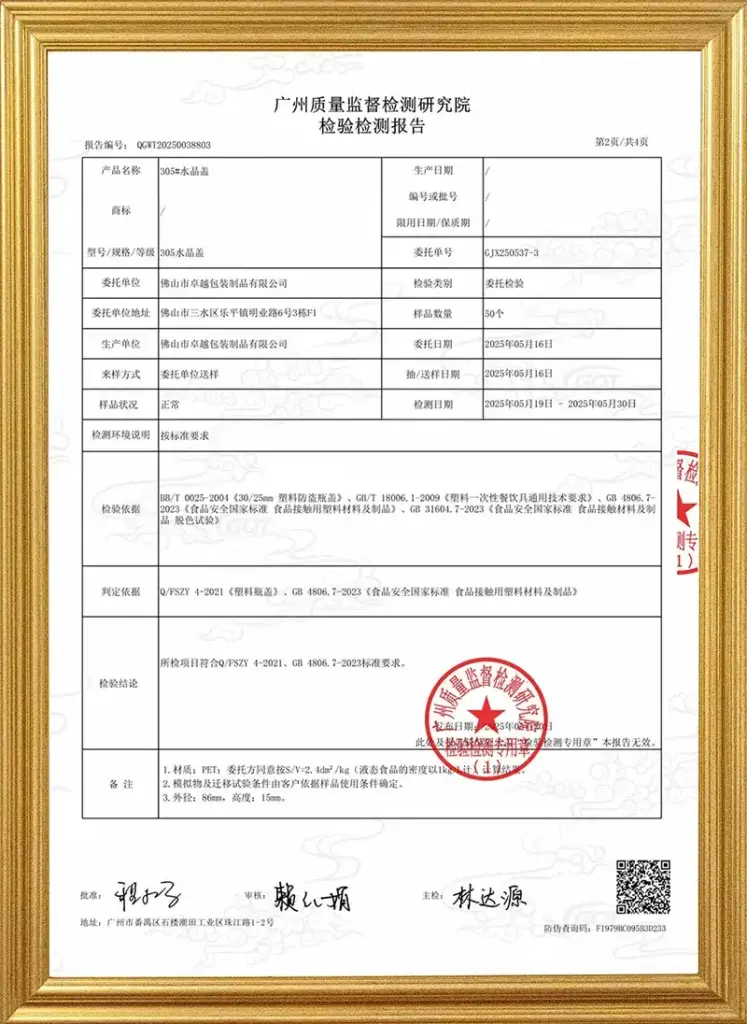

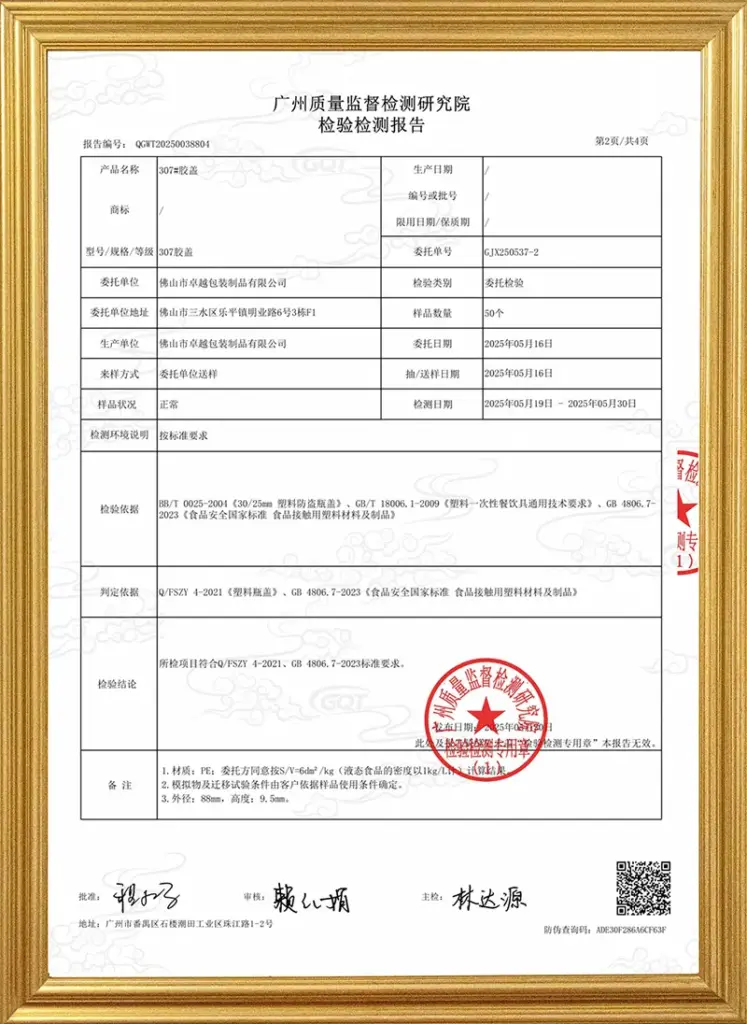

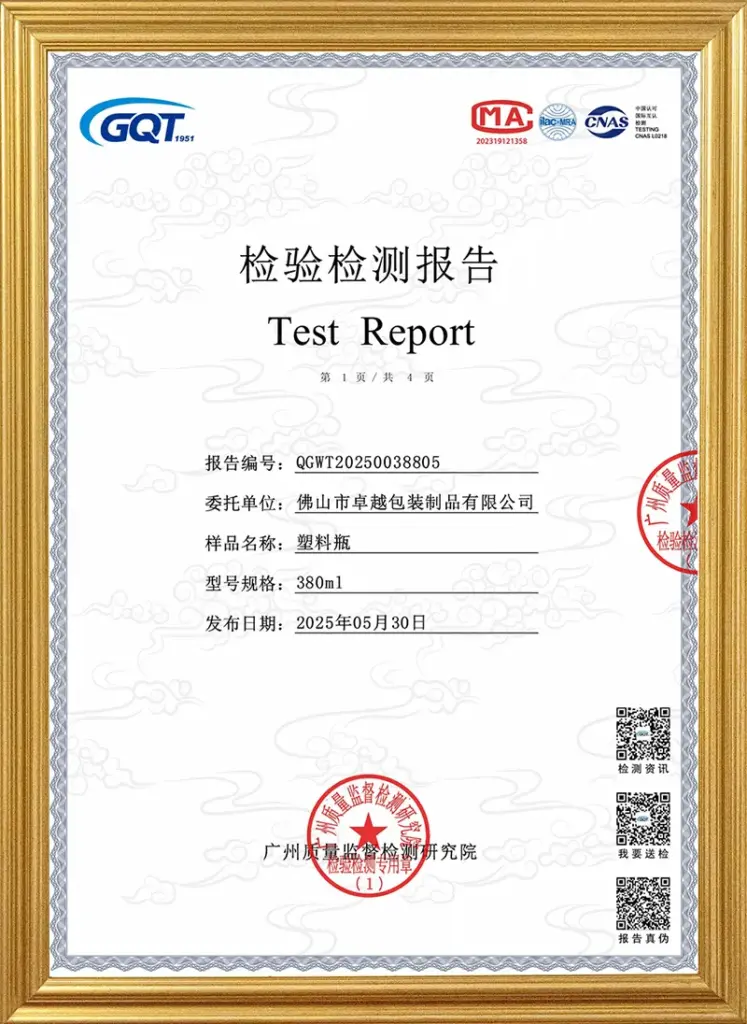

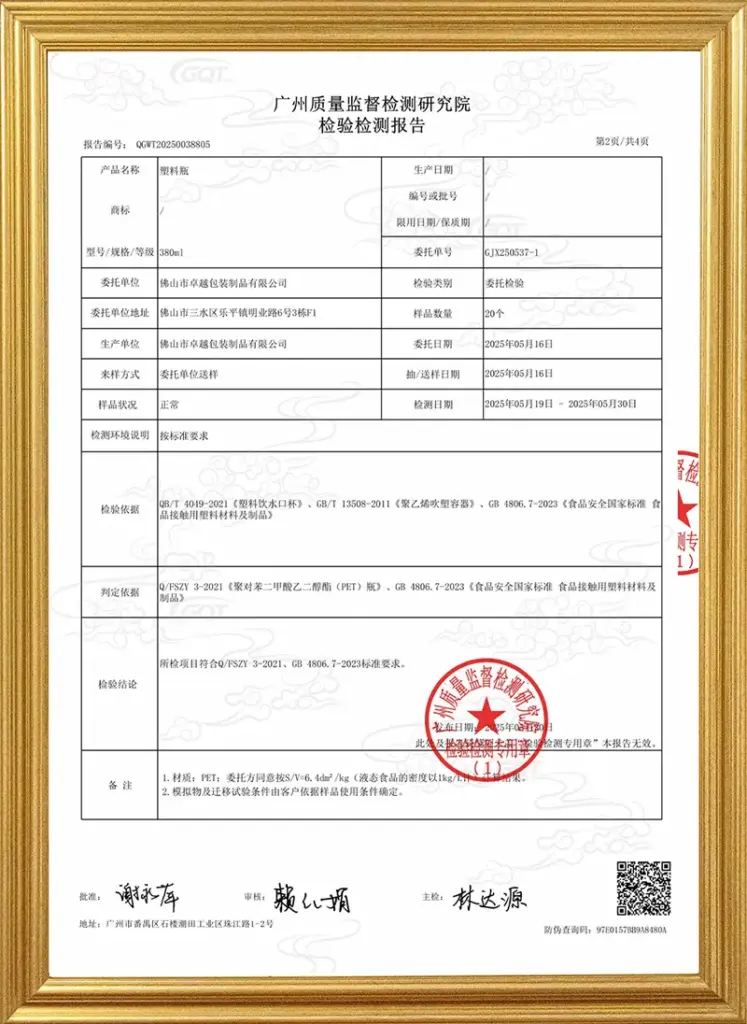

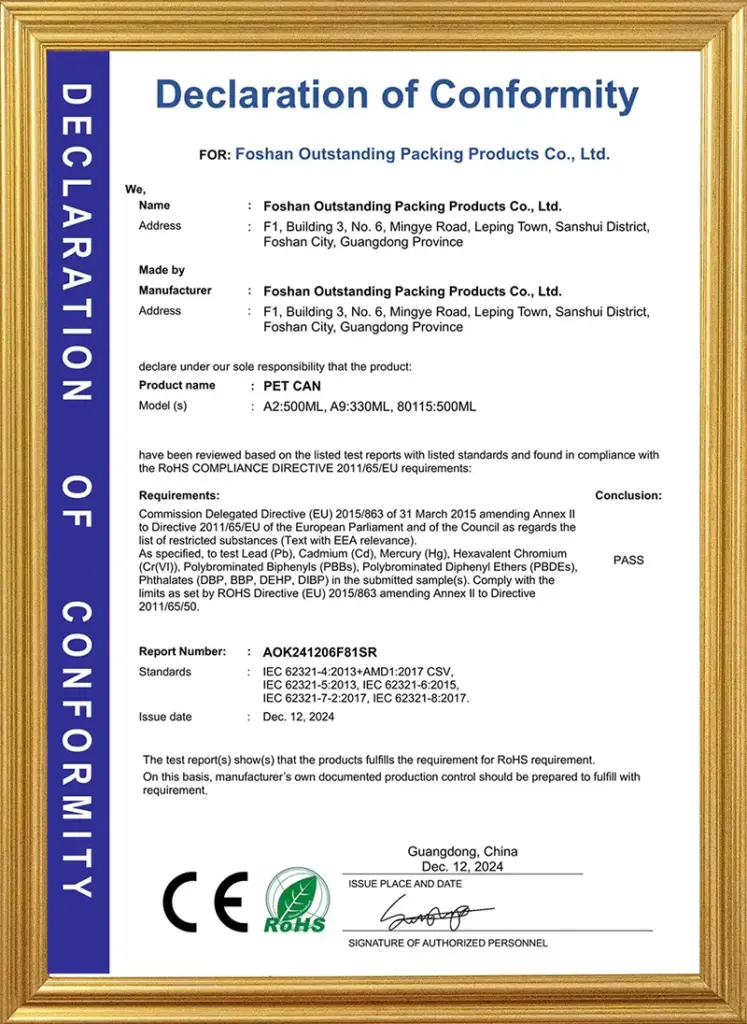

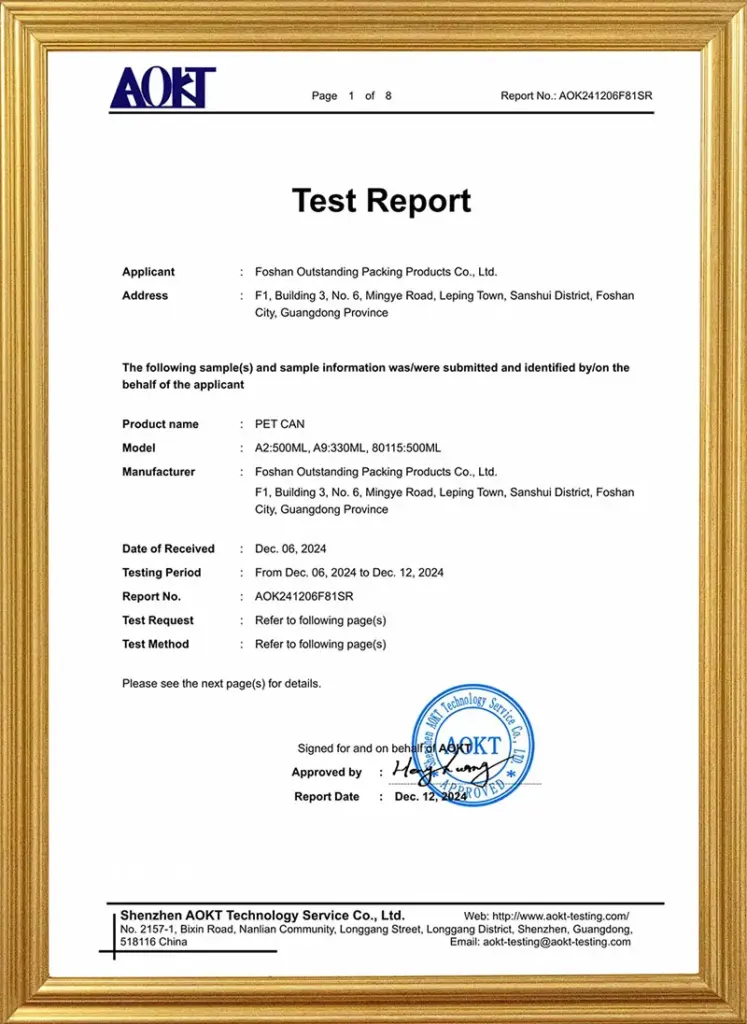

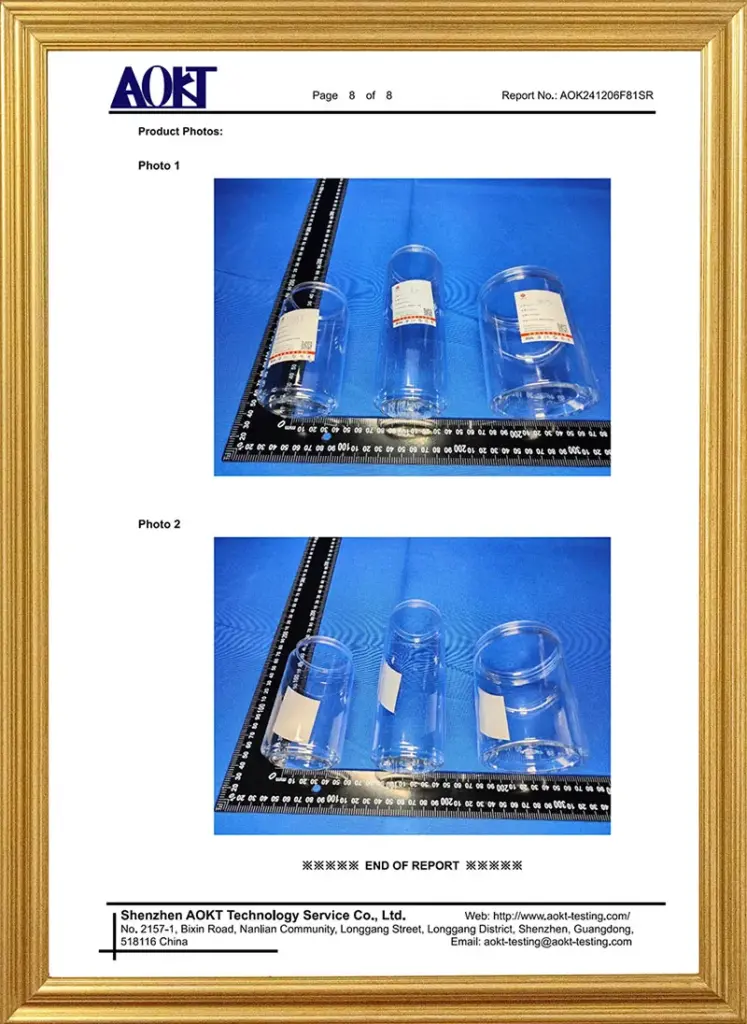

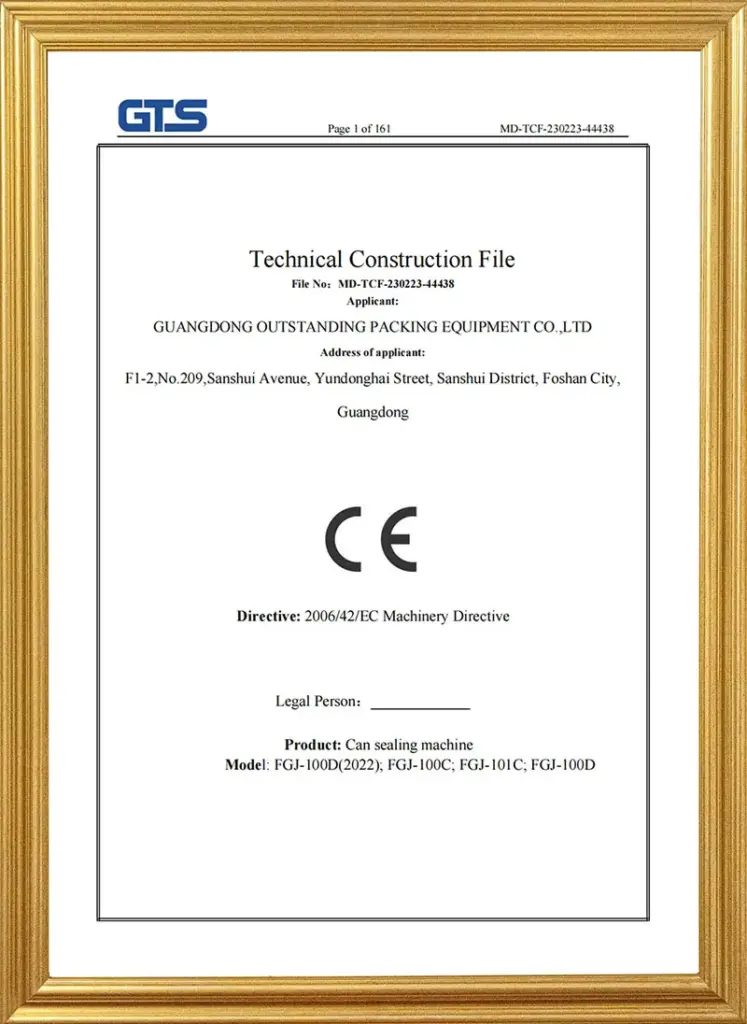

We submit products for comprehensive third-party testing quarterly, providing customers with detailed reports that confirm our packaging meets the highest international food-grade standards.

Our Rigorous Testing Process

Incoming Quality Control

Random sampling is conducted to assess the consistency of raw materials evaluating transparency, color, melting index, and moisture content. Additionally, we inspect the consistency and dispersion of all color masterbatches and verify the weight, dimensions, and wall thickness of incoming preforms, with all test results meticulously documented for full traceability.

In-Process Quality Control

We conduct real-time inspections throughout production.

In Injection Molding Process

Strict control over the preform production process:

- Preform Weight:Precision control within ±0.1g tolerance

- Preform Dimensions:The Length and diameter maintained within ±0.1mm tolerance

- Wall Thickness Uniformity: Multiple measurement points ensure error ≤0.05mm

In Blow Molding Process

Adheres to equally strict quality parameters:

- Transparency: Free from bubbles and impurities

- Bottle Mouth Flatness: Controlled within ±0.1mm tolerance

- Bottle Wall Thickness: Multiple sampling points verify consistency with ≤0.05mm deviation

Final Quality Control

Our final inspection ensures all products meet your requirements:

Appearance Inspection:

100% inspection, free from oil stains, scratches, black spots, and deformation

Dimensional Verification:

Measured within ±0.2mm tolerance

Sealing Performance Testing:

Vacuum or water immersion testing for zero leakage

Pressure Resistance Testing:

Strength testing to meet or exceed pressure standards

Drop Testing:

Simulated 1.8m drops with contents to verify impact resistance

Outgoing Quality Control

Before shipping, we perform final inspections to verify packaging integrity, accurate product quantities, and correct labeling. This guarantees your products arrive exactly as ordered and in perfect condition.